It’s an fact that the Rotary pouch packing machine computerized is among the top developments and many have some experience in the assembly of these machines. There are several areas to look for when choosing these machines. There are many kinds of machines that are available in various models. Each model is specifically designed to package the product in a particular way. The market for packaging holds enormous potential because there are an abundance of products that are continuing to come into the market. This is why these equipment’s are highly sought-after and hold a huge chance of development in the future.

Useful Pouch Packing Machine Characteristics

The most important aspect of the design of a bag packing machine’s function is precision of packing, which leads to the best dimensions, weight and cutting-off of the pouches. They are designed and operated in a manner that exceed every quality standard. They employ cutting-edge technology while creating these machines.

They provide perfect fix-up arrangements because they utilize the framework for fixing warmth. These machines fill pouches with food, close them, and then cut them. All of this occurs in one continuous process with these devices. They are especially essential for makers that make products that are made of powder or fluids.

Sorts of Machines

The machine frames Envelope Seal pouch device measures the total size of the product and then delivers the pouches by using a motion of film printed according to the pitch of the print and the framework for fixing warmth. It fills the pouches with seals them, and cut the pouches too. It’s a continuous operation. It is equipped with a vertical heat roller that is used for film nourishing. It is basically a mechanical drive heat roller that is fixed to the frame.

Another pouch packaging machine is the three-side seal bag framing and packaging, and filling machine, which is used to measure the amount of the item that could be in powder, granular or a solid structure. This time pouches are made using printed films that is performing very well. The framework for fixing warmth is used to ensure that pouches can be filled and cut in a smooth continuous process. This machine comes by the Touch board to control focal pressure along with the engine servo framework. This revolving frame that is used to play out the shape of the pouch, its filling and fixing capacities on an even course aids in ensuring a lengthy filling process and thus ensures straight fixing results. This allows for a long fixing time as well as lessening the impact of pinholes.

There’s a different machine that is also a three-side seal pouch filling and shaping packaging equipment with similar components to those mentioned above. The machine is equipped with an engine servo framework. Length of pouch could be adjusted via the control board, and it also has a irregular bars fixing frame. It has an excellent autonomous pivoting cutter inside this device. For more info about automatic filling sealing machine, Visit here: www.joygoalmachine.com

This pouch packing machine can be employed in the food packaging industry as well as fast food packaging, manufacturers of controlled and fluid items, and so on.

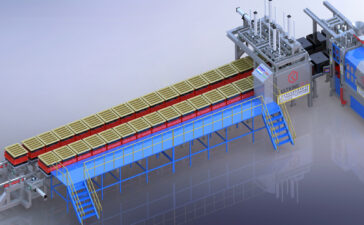

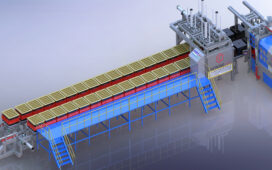

Shanghai Joygoal Food Machinery Co., Ltd. is an organization that is dedicated to the area of machinery for food production. We are a complete company that combines the research and development process, production installation, maintenance and production. We are equipped with the latest technology and experience, as well as expertly trained scientists and staff members to provide after-sales services. Our principal products are stand-up pouches for filling and cap-screwing machines as well as cup filling and sealing machines for sealing and filling bags, forming bag filling machines and liquid packing equipment as well as solid packing machines. strapping machines and vacuum packing machines. production lines for beverages, etc.