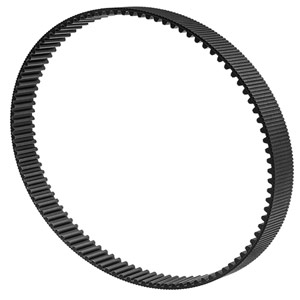

ZZR is one of the leading manufacturers of high-quality rubber timing belts, polyurethane timing belts, v belts, and other belts that are used in a wide variety of industries. They can supply large quantities of belts due to ready stock of the products in their warehouse. They have shipped all sorts of belts to clients worldwide for varied types of applications including power transmission, conveying, automotive industry, agriculture engineering, home appliances industry, etc. They have advanced product technology and machinery with highly trained skilled engineers and technicians to ensure that the products are shipped to clients only after undergoing thorough checks, trials, and audits. The company has made its products with long service life, energy savings, and low maintenance cost so that clients can focus on their tasks with low strain. Their unique Poly Chain Belt is constructed to provide better benefits than those of the competitors.

You may find that the belts do not need any lubrication and re-tensioning and have nylon coating protection so that oil, pollutants, and chemicals do not incur any damage to it. The belts are abrasion-resistant PU and do not generate dust and the carbon fiber reinforcement provides high strength and shock resistance.

V-Belts and Timing Belts

The V-belt is used to transmit power on the sidewall of the sheave and allows slippage which is desirable in certain types of operation. The V-belt is therefore a friction device. The timing belt on the other hand is a synchronous belt that remains very positively engaged as there are no slippages during its function. These belts wrap around the sprocket without the need for articulated engagement as in the case of chains. In this way, they eliminate both wear and tear and noise.

Even if there is a slippage in the synchronous belt then it will damage the timing belt as synchronicity is the prime reason why they are employed. Like V-belts synchronous belts are available in all types of sizes and constructions. The main difference is found when you look at the tooth, tensile chords, and type of compound used. They are either manufactured in rubber or polyurethane and this depends upon the applications. You may find more information from professional experts right here so that you can place an order for customized poly chain belts.

The advantages of V-belts are lower noise, economical, and allow slippages which can act as a safety measure and can be used for specific processes not easily possible by synchronous belts.

Advantages of Poly chain belts

Firstly, the poly chain belts perform exact shaft synchronization, low installation tension, low maintenance, higher drive efficiency, and longer life. The low installation tension allows for lower stress on shafts and bearings and is therefore economical in the long run.

You will also find that these chains have minimal vibration and also wide speed range and virtually no elongation takes place due to wear. Again, power transmission efficiency is not lost with use there is no need for lubrication and the chains are rust-free.

They are pretty economical because you don’t need expensive drive enclosures, a lubrication system, increased drive design options, no adjustments needed, and energy saving.