In precision industries such as pharmaceuticals, microelectronics, biotechnology, and healthcare research, the importance of controlled and sterile environments is paramount. Communicating these conditions’ needs for organizations can therefore only be achieved through NEBB Clean Room certification as per ISO 14644-1.Standard in operation NEBB rooms comply with ISO 14644-1 which entails the classification of air cleanliness based on particle concentration. This standard ensures that clean room performances are consistent and repeatable. The relevance of NEBB Clean Rooms, their alignment with ISO 14644-1, and how they benefit precision industries are covered in this article.

Benefits of NEBB Clean Rooms

Product Quality Assurance

One of the immense advantages of having such an environment is that it helps to guarantee the integrity or quality of their products. With ISO 14644-1 classifications, organizations can identify and maintain the right particle levels within their clean rooms.

Regulatory Compliance

ISO 14644-1 is a globally recognized document that has been adopted as a standard for cleanroom classifications. As well as meeting industry standards like those required by Food and and Drug Administration (FDA) and other regulatory bodies.

Precision and Consistency

ISO 14644-1 specification offers contamination limits necessary for various cleanroom classes necessary to maintain cleanliness that is relevant to their processes in other words, support is required for reliable measurement, controlled environments and consistent product quality.

Contamination Control

Contamination control is fundamental to clean rooms, and ISO 14644-1 helps address this. The standard also provides guidelines on particle concentration levels, air filtration systems, and other contamination control measures. NEBB Clean Rooms have advanced filtration systems, air pressure differentials, and uncompromising protocols to prevent the introduction or generation of particles, microbes, or any other contaminant in line with ISO 14644-1.

Conclusion

NEBB Clean Rooms adhere to the ISO 14644-1 Standard making them significant players in precision industries through offering controlled sterile and dependable environments. NEBB Clean Rooms abide by ISO 14644-1 classifications which guarantee product quality assurance, regulatory compliance, precision as well and cost savings related to contamination control. NEBB Clean Room certification combined with adherence to ISO 14644-1 standards enables firms to establish such essential conditions without which they cannot succeed in precise industries. Here are the Best 5 NEBB clean room suppliers.

1, CLEEMS

Website: https://www.cleanroom-system.com/

Since 1996, CLEEMS Cleanroom System Engineering and Material Co., LTD has been a prominent Clean Room Engineering & Consultant company in China. Specializing in supplying advanced clean rooms, CLEEMS caters to diverse client needs across various advanced industries. Clients include Intel, AMD, National Semiconductor (USA), STS Microelectronics, Sony, Roche, Baxter, Wyeth, among others. Established through a collaboration between Shanghai Electronics Engineering Design & Research Institute Co., Ltd (SEEDRI) and China Electronics System Engineering Co., Ltd (CESEC), CLEEMS continues to deliver optimal design and manufacturing solutions to meet the stringent requirements of its clientele.

2, GREAT Purification System

![]()

Website: https://www.great-panel.com/

Founded in 2005, GREAT Purification System has established itself as a professional manufacturer of cleanroom materials and a leading service provider in the industry. The company operates from a sprawling facility spanning over 25,000 square meters and employing 200 staff members, specializing in cleanroom enclosure systems. Over nearly two decades of development, GREAT Purification System has continuously upgraded its workshops with modern manufacturing facilities. These include digital control forming machines, laser cutting machines, bending machines, Amada CNC, and automatic panel manufacturing lines. Such investments have been made to enhance client services and foster stronger partnerships, reflecting the company’s commitment to delivering excellence in products and customer support.

Steel Door with Shape Connection

Hand Made Rockwool Sandwich Panel

3, Wiskind

Website: https://www.wiskindcleanroom.com/

Established in 1978, Wiskind specializes in cleanroom enclosure systems, boasting a vast facility spanning over 66,666 square meters and employing 2,000 staff members. With over 40 years of experience, Wiskind has garnered rich expertise in designing, manufacturing, transporting, and installing cleanroom systems. Committed to providing customers with the most reasonable and economical solutions, the company caters to industries such as biomedicine, electronic semiconductor, food, and new energy. Wiskind offers a comprehensive product system with rich categories, including cleanroom panels, cleanroom doors, medical doors, cleanroom windows, and more, all certified with FM, CE, SGS, ISO9001, and ISO14001. Over the past four decades, Wiskind has exported to over 50 countries and regions, earning the trust of local and international clients.

G-SILENCE Cleanroom Door With Aluminum Honeycomb Panel

Automatic Open Cleanroom Display Window For Pharmaceutical Visit Corridor Clean Room

4, Best Leader Cleanroom Technology

Website: https://www.bestleader-tech.com/

Best Leader Cleanroom Technology (Jiangsu) Co., Ltd. stands as a premier manufacturer of modular clean room systems, boasting over 20 years of production experience. BSL offers comprehensive materials and solutions in clean room engineering, serving as the preferred partner for foreign-funded companies in various sectors, including pharmaceuticals, biochemistry, and electronics.

BSL’s commitment to “creating value for customers” is evident in its focus on understanding and addressing the individual needs of clients. The company provides professional engineering consulting, planning, design, construction, system operation, and maintenance services, ensuring that customers receive tailored solutions that meet their specific requirements.

5, WONCLEAN COMPANY LIMITED

Website: https://www.wonclean.com/

Established in 2005, WONCLEAN COMPANY LIMITED has emerged as a leading provider of modular laboratory and cleanroom systems catering to industries such as pharmaceuticals, medical devices, food, and electronics. Specializing in modular laboratories, cleanrooms, wall panels, ceiling panels, HPL sandwich panels, lighting systems, HVAC system materials, and equipment, we offer cutting-edge solutions designed to meet stringent industry standards and requirements. Our product range undergoes meticulous design and quality control processes, utilizing advanced technologies and materials to ensure high-performance and reliability across various cleanroom environments. With a dedicated team comprising 5 design professionals, 30 production personnel, and over 50 construction engineers, WONCLEAN is committed to delivering excellence.

Our design team employs state-of-the-art 3D drafting techniques to provide customized solutions tailored to the specific needs of our clients. Meanwhile, our production team adheres to efficient manufacturing processes and a stringent quality management system, guaranteeing timely delivery of top-notch products. At WONCLEAN, we strive to exceed customer expectations by delivering innovative solutions with uncompromising quality and reliability.

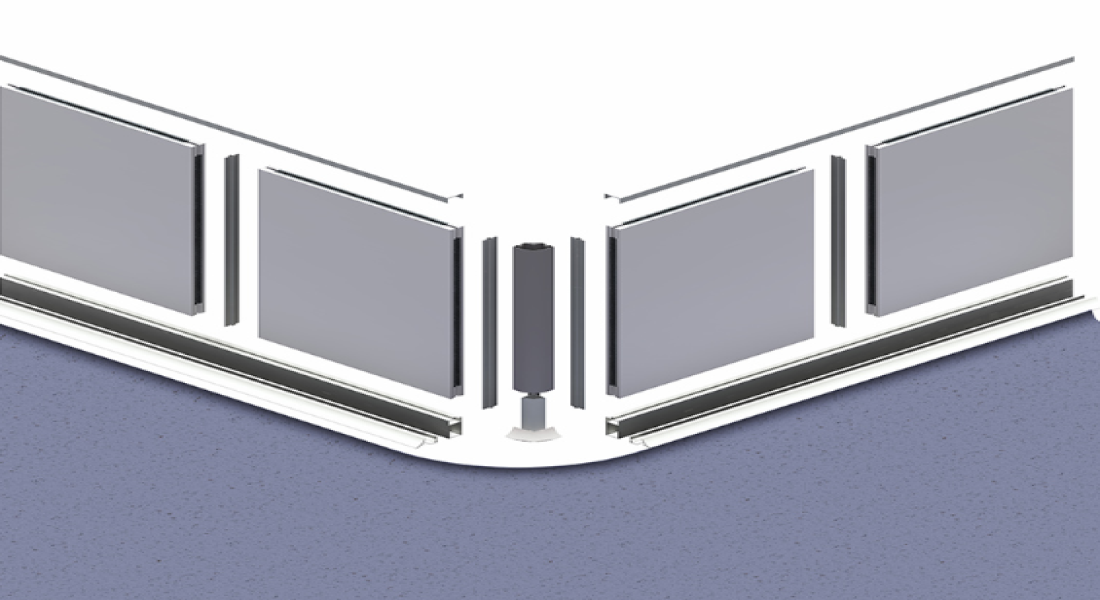

Modular Clean Room Overall

Clean room Partition System