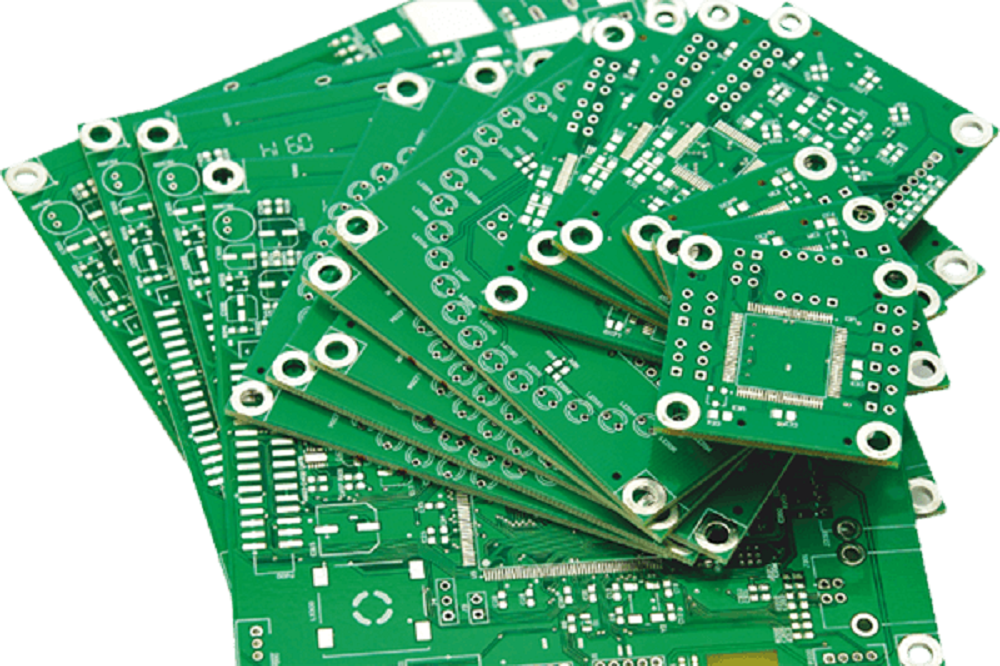

PCB or Printed Circuit Boards are referred to as independent module comprising of several interconnected electronic parts. A thin layer frames consisting of a quality material are used to imprint on the protecting board’s surface called the substrate. But to ensure getting the best quality pcb assembling units, you need to select only certified manufacturing companies like aipcba.

Need for pcba

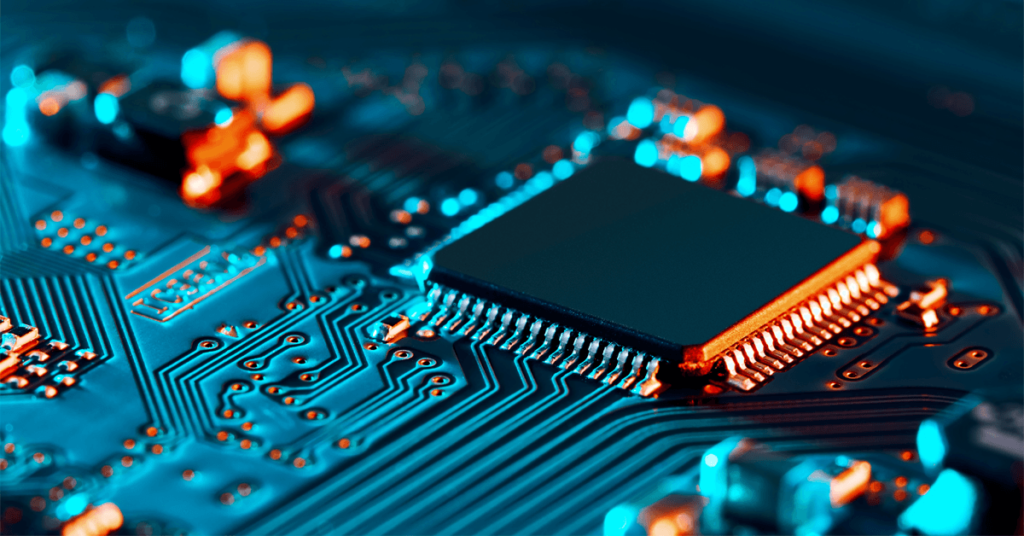

In today’s modern age, there have already been launched different types of gadgets and electronic equipment’s. However, their production is not possible without using a PCB. The components and assembly along with incorporated circuits are termed to be the fundamental components present in the gadgets. They tend to constitute the very foundation of every hardware bit necessary for efficient and smooth functioning of the electronic product. The PCB provides increased functional ability to the electronic item. For instance, it includes various parts like capacitor, resistor, pots, loops, FET, diodes, transistors, transformers, OCs, etc. All these take the shape of the whole electronic circuit. PCBs not only provide the network with essential electronic segments. It also reduces the size as well as expands the electronic gear’s overall effectiveness.

The PCB components present on the printed circuit board basically are electrically connected with circuits using specific techniques. Every part comes fitted with leads or thin wires. They are then pushed across small holes that are drilled within the substrate or base board. Then, it is welded to the affiliation pads present in the circuits on contrary side. Discussing with the professionals at https://www.aipcba.com/ can give you a clear idea about the production process.

What are the commonly found components?

They are as follows:

- Capacitors (tantalum, electrolytic, ceramic)

- Resistors

- Transistors (JFET, BJT, MOSFET)

- LEDs

- Switches

- Inductors

- Fuses

- Integrated circuits

- Motors

Rough estimation will be necessary of the location of the different parts to be fitted in the pcb assembly unit. This is to be done before continuing with point-by-point PCB format and outline. Carrying out this task is sure to help empower you with several choices concerning layer quantity that is essential in the board. Also is taken into consideration if there is present adequate space to fit all assembly and components hardware within. The PCB configuration and format affects mostly the way how the circuit functions. On outlining the pcb assembly successfully, the circuit at that point in time is likely to perform more dependently as well as within its determination. Moreover, it will not be used exclusively to produce the original pcba unit. But the records are likely to be used as parts in different places within the assembling procedure. It is essential to understand that the PCB configuration is quite different from that of the fundamental board outline.

For turnkey pcb assembly quotes, you need to contact the registered manufacturers and specify your specific business requirements to them. They will create a prototype based on your needs and demands and accordingly you can finalise the one that will go for mass production.