It requires not just high technology, but a whole line of quality controls and checks to determine the highest level of safety standards such that risk free LPG cylinder is rolled out from a factory. In this context it is quite certain that only very few manufacturers actually come up to this standard with guaranteed service. If any one cylinder on the assembly line has an issue then the whole lot gets for check up or should as is the case with quality manufacturing.

It is therefore quite essential for gas cylinder to be able to perform as a pressure vessel for storing LPG for a very long period of time. Usually, LPG cylinders are manufactured under controls and specifications of a particular country. As per ISO specifications LPG is low pressure liquefied gas that is composed of one or more light hydrocarbons. This means that it includes mainly of propane, butane, butane isomers, butene, propene and traces of other hydrocarbon gases.

For your specific queries you may contact at www.lpg-cylinder-ng.com for prices and catalogues.

Quality Leak Proof LPG Cylinder Manufacturing

If you wish to go for long contracts on distributorship or retailing of LPG then you must contact an authentic and reliable LPG manufacturer. This is very important for when you are building large clientele base for your gas then you must be in a position to give suitable assurance about the quality of gas as well as cylinder.

For your whole requirements you may find reliable source of TIANLONG LPG CYLINDER as these are of high quality materials. There is little to doubt that customers always aim for the best service and if they don’t get it at one place they easily move off to another.

It is therefore quite important to keep international standards as per specification as well as even a little higher. In fact, when it comes to bottling of gas in cylinders, even the valve body, valve stem, valve outlet and valve operating mechanism has to be as per the standard rule.

Then there are eduction tube, liquid level indicator, fixed liquid level gauge, excess flow valve, non-return valve, sediment tube and pressure relief valve to be well designed and of high quality make. All these specifications are given in International Standards Organization’s terms of manufacture of LPG gas cylinder.

Safety Requirements and Controls

For a modern plant producing LPG gas there ought to be a system of proper rigid controls during its assembly when gas is filled into each cylinder. Even during the process of manufacture of LPG cylinder companies make sure that they have each and every part of operation scrutinized by skilled technicians for safety requirements.

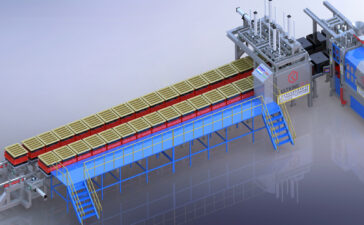

Only with advanced technological tools and equipments can LPG GAS CYLINDER MANUFACTURER are able to meet these high standards required from them. In order to manufacture LPG cylinders initially large steel sheets need to be cut in size on modern cutting machine. This is done to make blanks. Later, these blanks are deep drawn with the drawing power of powerful presses. The result of this is two halves of a cylinder that is sealed together in fully fool proof manner.

LPG containers have unique pressure relief valves as these will automatically go off and release the gas outside when it becomes heated due to outside sources. Therefore the minimum standard requirement of wall thickness of LPG containers is usually not less than 1.5 mm.

High Quality Refilling Facilities and Distribution Network

There is no denying the fact that LPG containers have to be refilled in much secured atmosphere. Here, skilled labor and technology ought to go side by side for riskless output. As both LPG tanks as well LPG cylinders are inflammable it is prone to explosion if suitable quality materials are not used.

You would find that the above site has world class bottling and filling plants so that customers needn’t have any apprehension or risk of explosion. It is seen that this LPG GAS CYLINDER COMPANY has requisite standard for its tanks as well as has good fire resistance ratings. This would mean that their risk is much lesser than many other competitors worldwide.

Typically, they are able to establish enlarged fire resistant designed tanks for stocking LPG for future supply too.